What is a helical gear?

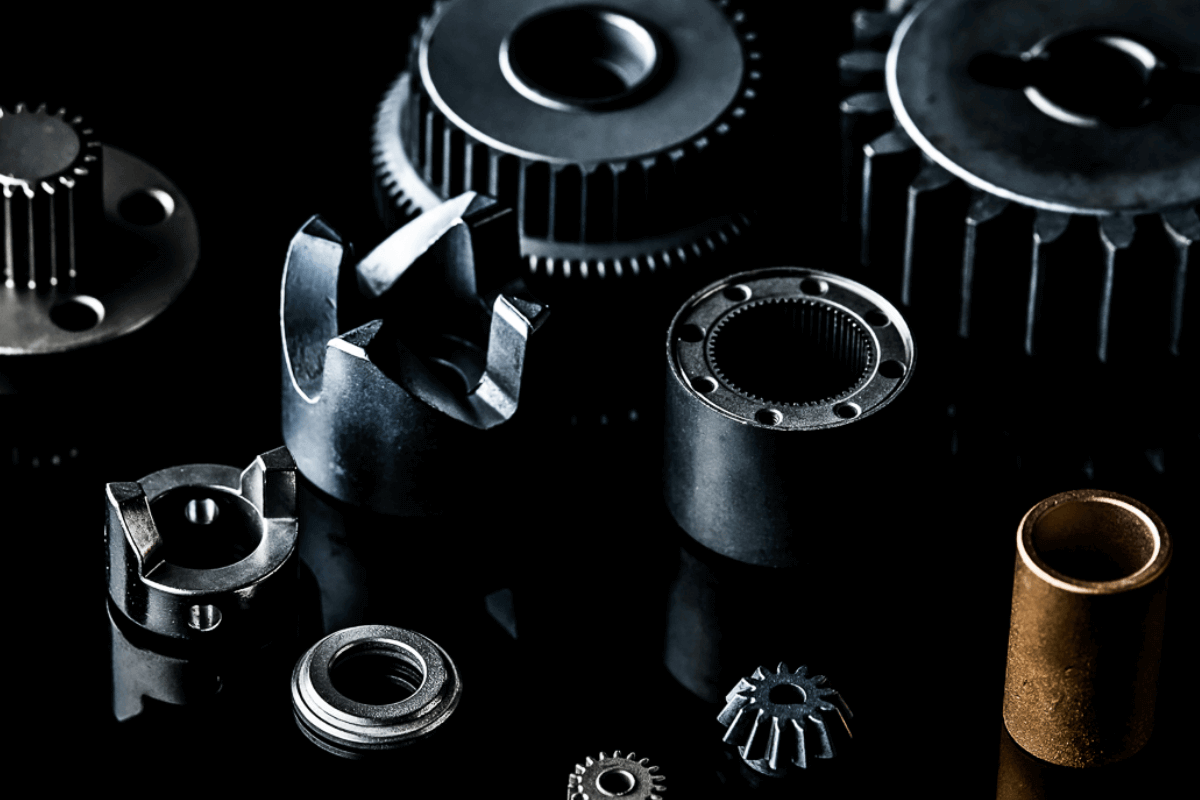

Helical gears are called helical gears in English. While the teeth of ordinary gears are straight, the teeth of helical gears are spiral. The spiral tooth pattern increases the meshing ratio between the gears, and the strength of the tooth surface is higher than that of spur gears. Although the tooth surface of helical gears is strong, it is important to check the allowable bending load. The strength of the tooth surface is an indicator of whether the gear is rotating safely enough in the direction of travel. In order to prevent wear on the tooth surface, the tooth surface must be hardened, and a material that can be carburized and quenched is used. If the gear is rotating, a material with high bending strength is required to prevent damage to the gear. In that case, a material that can be induction hardened after quenching and refracting is used.

Characteristics of helical gears

Helical gears are written in kanji as "helical teeth," and as the kanji suggests, the teeth are slanted. You can also think of them as spur gears stacked at an angle.

Because the teeth mesh continuously, the rotation is smooth and vibration is suppressed. Even at high speeds, noise is not generated and the number of teeth meshing at the same time is increased, so the teeth contact is dispersed, noise is reduced, and torque fluctuation is small, making it used for relatively high loads. When in use, the gears are parallel and gears with different left and right axes are lined up.

Taking advantage of the fact that the shape of the teeth is twisted in the circumferential direction, helical gears can transmit power in a direction perpendicular to the rotation of the shaft, which is not possible with spur gears.

Helical gears and twist direction

Gears with twisted teeth, such as helical gears, have fixed combinations. The direction of the twist is along the central axis of the gear. If the teeth rise to the right when viewed from the front, it is a "right-hand twist," and if they rise to the left, it is a "left-hand twist."

In addition, the meshing condition for a pair of helical gears is that they have different twist directions.

Applications and usage examples of helical gears

Because they are stronger than spur gears, they are used in automobiles, industrial robots, machine tools, reducers, power tools, agricultural equipment, and other areas that require strength. Japanese automobile manufacturers, in particular, have high standards for noise levels, and do not use spur gears, which are the general gear type. However, spur gears are used in racing and other areas where noise is not an issue.

In addition, because they are resistant to heavy loads, they are used in heavy industries such as power plants and cement mills. It is important to use gears made of materials suitable for each application, but in addition, to prevent gear trouble, it is necessary to form an oil film. This prevents direct contact between the friction surfaces when the gears come into contact, and can be oil, grease, compound, etc. Oil lubrication in particular is often used for sealed gears, and is often used in high temperature and high speed operating environments because it has cooling properties.

Advantages and disadvantages of helical gears

The advantages are that it is stronger and quieter than general spur gears. The meshing ratio between the gears is high, vibration can be reduced, and power can be transmitted quietly and stably. On the other hand, the disadvantage is that thrust loads (force applied in the axial direction of the gear) must be taken into consideration. If they are installed without taking this into consideration, it can cause wear and rotation problems. Since it requires advanced technology, the manufacturing costs are often high. To deal with thrust loads, it is recommended to use angular ball bearings or tapered roller bearings. The former are suitable for applications requiring high speed rotation and are capable of receiving combined loads. The latter are designed so that the apex of the conical surface of the bearing intersects at a point on the center line of the bearing, making them suitable for applications where heavy loads or shock loads are applied.

What is a double helical gear?

Double helical gears are also called double helical gears. They are a combination of left-handed and right-handed helical gears. Conventional helical gears can be subjected to thrust loads, but double helical gears cancel out thrust loads by combining symmetrical helical gears.

One of its features is that it has a higher meshing ratio than normal helical gears, which allows the teeth to mesh smoothly even when rotating at high speeds, transmitting large amounts of power while preventing noise.

The difference between helical gears and worm gears

Helical gears are primarily used to transmit rotational motion.

On the other hand, worm gears are "skewed" gears, meaning that the two rotation axes are not parallel and do not intersect. They are also generally used to reduce the reduction ratio. Both gears have slanted teeth, and are often thought to have similar functions, but they actually have different functions. Also, helical gears use gears with different helix directions, whereas worm gears use gears with the same helix direction.

The difference between helical gears and spiral gears

The pair of a helical gear is a screw gear. A screw gear is a gear whose teeth are twisted in the axial direction. Used alone, it is no different from a helical gear, but unlike a helical gear, it is used perpendicularly rather than parallel to the helical gear. Although screw gears are not very strong, they can achieve a high reduction ratio even in a small size, so they are used in small gearboxes. Helical gears can be manufactured using cutting, grinding, casting, and pressing.

For helical gears, go to Kiyota!

We will propose the optimal shape, manufacturing method, production base, and logistics according to your specifications and requests. Since we have sales bases overseas, we can provide you with the best price in one stop. If you are having trouble sourcing helical gears, please feel free to contact us!

FAQ

Question: What are helical gears?

Answer: Ordinary gears have straight teeth, whereas helical gears have spiral teeth. The spiral tooth pattern increases the meshing ratio between the gears and makes the tooth surface stronger than that of spur gears.

Question: What are the characteristics of helical gears?

Answer: The kanji for helical gears is "helical teeth," and as the kanji suggests, the teeth are shaped at an angle. Because the teeth mesh continuously, rotation is smoother and vibration is reduced.